Sizing- This is when the shank of a ring is either shortened or lengthened to improve the fit of the ring. The size required is determined by a set of ring gauges which use the letters of the alphabet to indicate the size required. ( "A" being the smallest). The ring should fit tightly on the knuckle but still be able to pass over it. To decrease or size down - a piece of the shank is cut away (approx. 1mm per size decrease) . To increase or size up the shank is cut and a gap made to accommodate the additional metal (1mm per size increase)

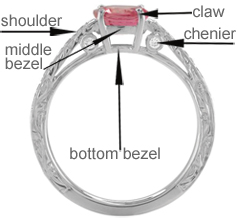

Claws- (See a claw in the image Parts of Ring Head B) Through general wear and tear the claws of a ring are worn down and this can lead to the loss of stones from a setting. A point to note we are often asked to supply one claw only, it is very rare that one or two claws need replacing only. When one claw falls off it is likely that the others are weak. It is more likely that all claws would need replacing, it is recommended that the item is sent in so that, the whole setting can be checked and an estimate will be provided for the work needed.

Reclawing- involves the removal of the stone from a setting, if it hasn't already fallen out, the old claws are then cut away to the base , new claws soldered on and then any stones are reset. Please allow 3/4 weeks for this process. We suggest mentioning to your customer that the alteration will tend to change the appearance slightly of the setting as the worn areas will have extra gold added.

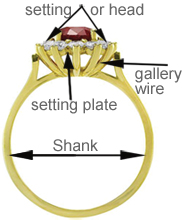

Shanks- (see the shank of a ring in the image Parts of a Ring A) It is sometimes necessary to replace the shank of a ring when there has been excessive wear or damage to either the back of the band or less often the complete area of the shank including the shoulders. The process involves cutting away the worn or damaged section and then soldering a new piece into the ring. The ring is then sent to the assay office for hallmarking, this is required by law. The process takes approx. 4-5 weeks. Shanks are also replaced if sizing the ring would make the shank too thin, when the gold used in the manufacturer of the ring is faulty, when the shoulders are too thin to support a 3/4 shank, or a customer wants to change the colour of the metal for example from white gold to yellow gold.

Setting- (see the setting or head of a ring in the image Parts of a Ring A). A new setting or head is needed if the sides, as well as the claws, of a setting are worn. Claws cannot be soldered onto a feeble base. It can also be used to change the look of a ring by either altering the style of a setting e.g. from claws to rubover setting or to change the type of metal used e.g. yellow to white gold. The process involves removing any stones from the setting , removing and replacing the old setting and then resetting any stones. This process usually takes 3-4 weeks. It is advisable to mention to your customer that the alteration will tend to change the appearance slightly of the setting as the worn areas will have extra gold added.

Read in detail about the different settings here.

Rebuilds- This process is undertaken when the sides or parts of a setting are worn away, usually on a ring that is not claw set. A piece of metal is soldered over the worn section and shaped to fit the original look of the ring. It is advisable to mention to your customer that the alteration will tend to change the appearance slightly of the setting as the worn areas will have extra gold added.

Hallmarks-These are the authorised stamp impressions that indicate maker, standard of fineness and the Assay office the Hallmark was issued. Older hallmarks also include the year of manufacture, this is symbolised by a letter the font of which changes with every cycle of the alphabet. They are required by law if a piece of gold (9ct,14ct,18ct and 22ct) or platinum weighs more than 1 gram (7 grams for silver). Some rings have very faint hallmarks and these can be removed by the sizing process, this should be anticipated and the customers advised accordingly. Any rings requiring Hallmarking have to be sent to an Assay Office, allow three weeks for this process. Points to note, if a previous repair has been undertaken using an inferior metal e.g. silver instead of white gold, the item will fail the assay. New items which we supply will of course require hallmarking.

Please note imported rings may have laser hallmarks, these hallmarks are only burnt on to the surface of the metal by a laser they can be very faint.

Read more about Hallmarks here.

Castings- This is the process used when many of the same item are required. A rubber mould is made of the original piece of jewellery to be copied. The original piece of jewellery is removed and a cavity is left which is then injected with liquid wax which cools, making a replica copy. The wax is then covered with a similar solution to plaster which dries solid to form a casing. The wax is burnt out and molten gold is poured into the casing using centrifugal force to ensure the gold fills every detail to make a clone of the original.

Handmade Mounts- This is when a customer requires an original design not available from the casting supplier or when they express a preference for a handmade mount. The process involves receiving accurate instructions and drawings that detail the customers requirements and can take 5-6 weeks.

Remounts- We can remount most styles of rings. Remounting involves changing the head and sometimes the shank of a ring but still using the original stones. We can source many different styles of settings and usually are a good match to the original. These are available in all types of metals including different carats of gold, white gold and platinum. If a particular style is not available we can hand make to match best possible. This takes a little longer to do and is often more expensive but enables us to re-create any type of ring or setting. We can also make most types of rings/settings from specific drawings. We can provide an estimate detailing the work required and costings before we proceed with the job.

Gemstone and Diamond Supply- we stock a large range of the most common gem stones including diamonds and can supply a variety of grades and sizes. We have suppliers who can provide the more unusual stones. If necessary we can supply stones on approbation (appro) for you to show your customer under no obligation to buy. We can also supply and cut stones to fit settings if they are not stock sizes.

Recut, Repolish- on some softer stones e.g. opal, emerald and garnet the surface can wear away and may, after some years, need to be repolished or recut by a lapidary (a stone cutter). The harder stones such as diamond, ruby and sapphire can also chip or wear over time and these can also be recut. The cost price does vary according to the amounts of facets (surfaces of the stone) the size and its hardness. The procedure can take 3-6 weeks. In some cases it is cheaper to replace the stone than have a damaged stone recut.